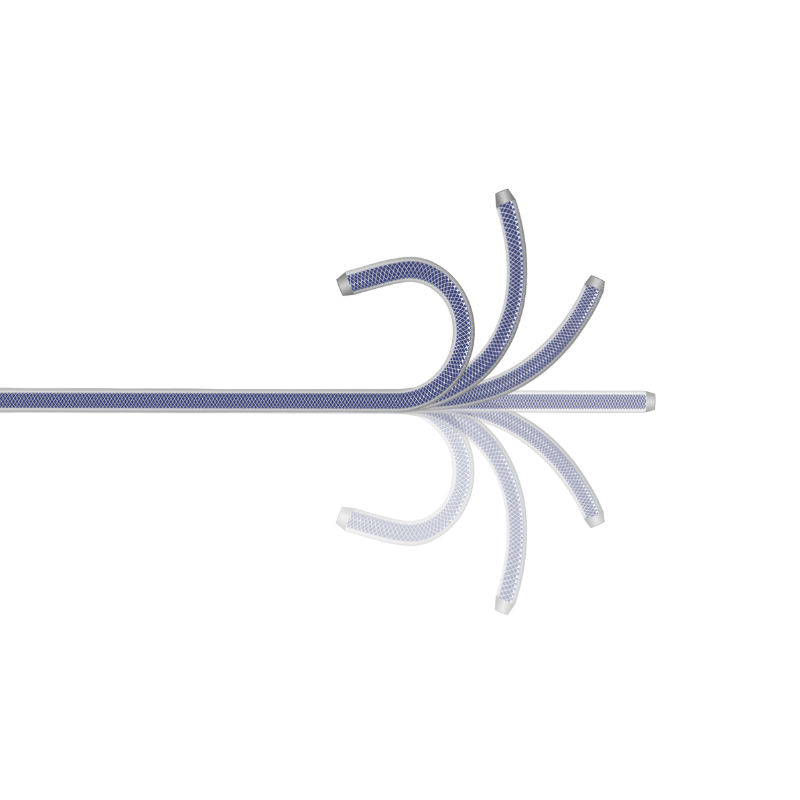

- Kink Resistance

- Pushability

- Trackability

- Crossability

- Torqueability

- 7 Days Lead Time

Fast production of high quality custom medical composite catheters in 7 days. - No Minimum Quantity

Build to suit your testing needs. We can build ten, five, even a single unit for your unique design. Pay for parts you actually need!

- Size Range:1.7-36F

- Concentricity:90%

- Outer Layer Material: Multi-durometer Pebax, TPU, Nylon, PA, PI, PET, etc

- Inner Layer Material: PTFE, FEP, PEBAX, PA, TPU, PET, HDPE, etc

- Braid Material: Stainless Steel, Nitinol, Tungsten, Nylon, Aramid, LCP, PEEK, etc

- Braid Wire Types: Round wire, Flat wire, Round and Flat wire mix

- Braid Density: 20-200 PPI, Variable density/pitch

- Braid Angle: 20-70 degrees

- Reinforcing layer structure: braided, coiled, braided + coiled, snake bone, hypotube

- Braid Pattern: 2x2, 2x1, 1x1

- Supports anti-torsional braid (4 layers)

- Supports variable diameter tubes

- Supports stainless steel tubes + Braided tubes

- Integrated independent research and production of inner liners, outer jackets, and heat shrink tubes

- Providing excellent one-stop hydrophilic, anticoagulant, and antimicrobial coating services

- Fully closed-loop advanced equipment, mature processes, and consistent quality

Neurovascular, coronary, peripheral, structural heart disease, electrophysiology, urology, gastrointestinal, nephrology, endoscopy, respiratory, etc.

>Ultra-small size: Easier to pass through narrow lesions or small blood vessels

>Ultra-thin wall with a large inner lumen: the innermost layer uses a self-developed ultra-thin wall PTFE liner, providing greater internal space, excellent delivery performance, and smoother operation

>Fully closed-loop advanced equipment, mature processes, and consistent quality

>Distal marker band: Superior trackability, clear visualization, and precise positioning

>Multi-directional deflection: offers maximum configurability, from small tip deflection to full range of motion

>Precise control: Provide more accurate catheter positioning, precisely target the lesion site

>Precise control: Provide more accurate catheter positioning, precisely target the lesion site

>Custom handle: Easy to operate control mechanism, ergonomic handle design

>Excellent support: Exceptional shape retention and higher torque for stable support

>Ultra-smooth inner and outer surfaces:

Innermost layer: Ultra-thin PTFE liner, excellent delivery performance, smoother operation

Outermost layer: Segmented application of hydrophilic coating, designed for critical applications

>Device compatibility: Compatible with a variety of different diameters/types of catheters and devices, providing excellent visualization

jMedtech excels in the specialized design, development, and production of Reinforced Tubings. Our collaborative approach ensures that we meet the unique requirements of our clients effectively. We provide a diverse selection of sizes, materials, and braid configurations. Tailored sizes and designs are also available upon request.

For further details about our catheter manufacturing capabilities, or to request a sample or quote, please contact us via email at [email protected].