jMedtech hydrophilic coating equipment is specifically designed and developed to match the properties of the coating material and the requirements of the hydrophilic coating process. With advanced automated coating systems and precise coating automation, the equipment enables consistent hydrophilic surface treatment and stable production quality. Acting as a high-performance automatic coating machine, it supports large-scale manufacturing by ensuring efficiency, reliability, and repeatability. This makes it possible to achieve automated mass production of coated products with outstanding efficiency and performance.

○ The jMedtech hydrophilic coating equipment adopts a five-stage lifting system with variable-speed pulling to improve coating precision.

○ During UV curing, the product rotates at a constant speed, ensuring uniform curing energy and reliable hydrophilic surface treatment.

○ Equipped with 12 light-intensity test points for accurate monitoring and stable hydrophilic coating process control.

○ The operating program supports easy use and efficient coating automation within automated coating systems.

○ A color LED touchscreen interface allows operators to edit and store coating parameters, making it a reliable automatic coating machine for consistent automated coatings.

| Device model | JMT-QSTC |

| voltage | 220/50Hz>26A |

| equipment power | 5000W |

| Safe current and voltage | 220V/32A |

| ambient temperature, humidity | 15~35°C0~80% |

| Number Of light Troughs | 6(3Row X2Column) |

| Core Controller | Core Controller |

| Fan Flow | 1080m³/h |

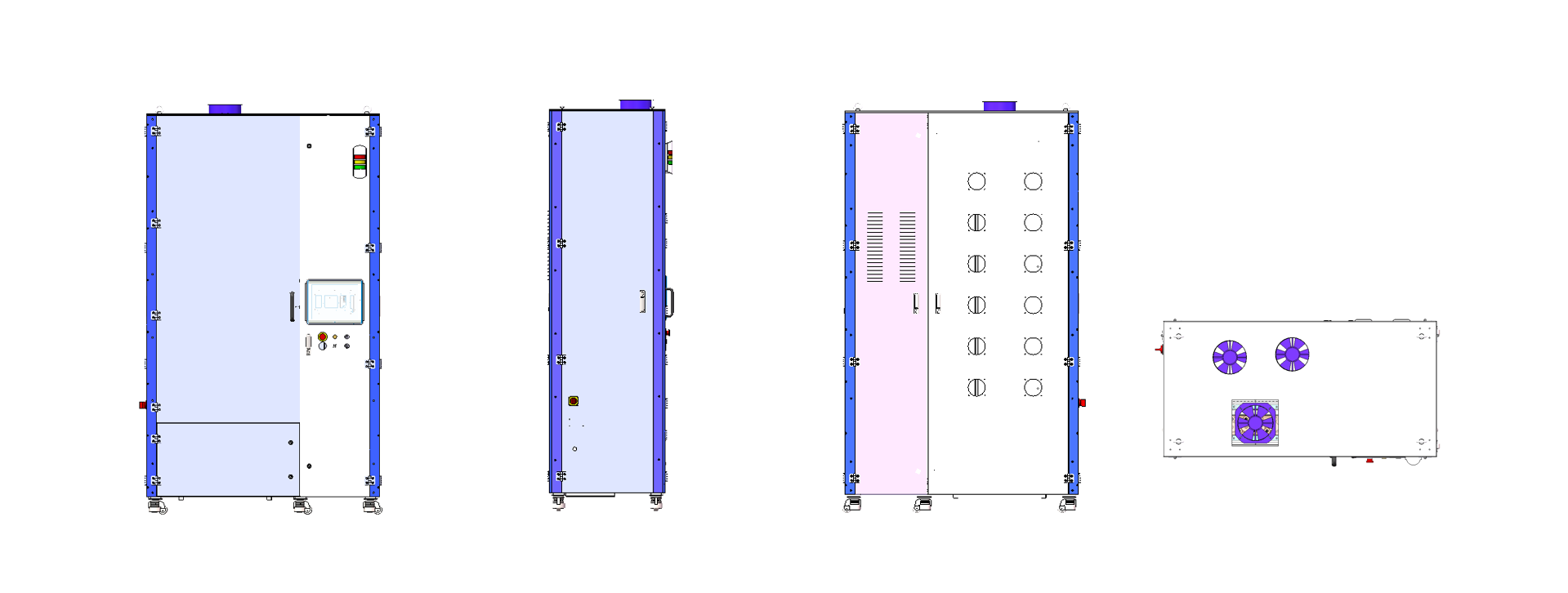

| Device Size (Host) | 1530*760*2200(mm) |

| Radiant Energy | >35mW/cm² |

| Coating Position Accuracy | ±0.05mm |

| Speed | 0~100mm/s |

| Product Rotation Speed | 1~20 Rpm |

| Can Store Product Process Parameters | 100 |

| Solution Tube Material | Medical HDPE |

○ Compatible with conventional sheaths, catheters, and guide wires.

○ Supports luer head integration within the hydrophilic coating process.

○ Coating solution chamber can be customized according to catheter diameter and length for precise hydrophilic treatment.

○ Automatic straightening function: non-straight catheters can be corrected using customized tools, improving efficiency in coating automation.

○ Balloon catheter capability: inflation can be performed before coating, enabling reliable hydrophilic surface treatment with jMedtech hydrophilic coating equipment.

Technical Resources

Download more information on how our Hydrophilic Coating Equipment and expertise can tackle unmet needs.