Product Introduction

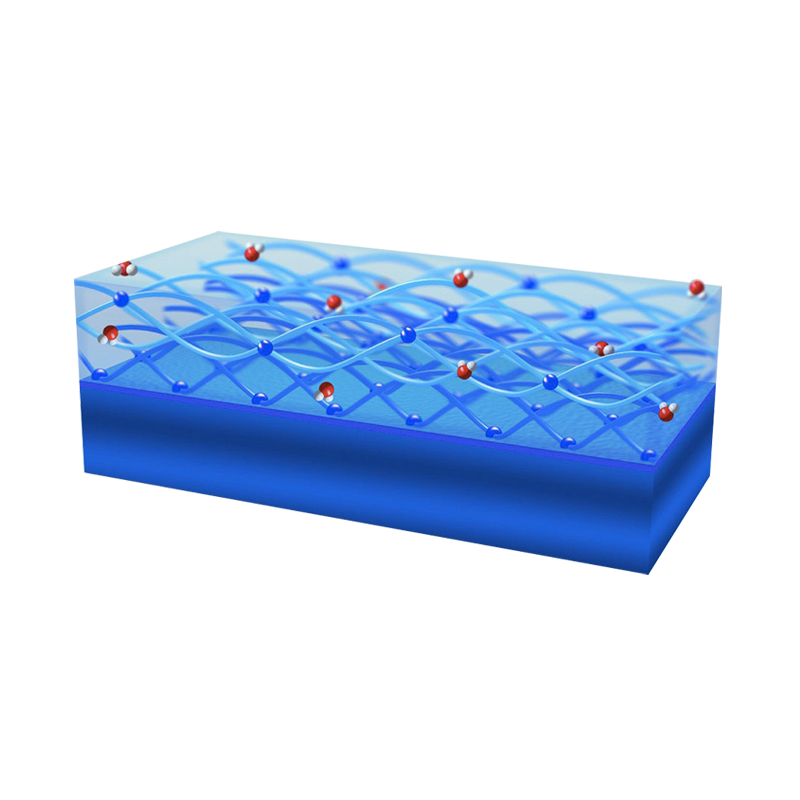

Patented Hydrophilic Technology

The patented jAqua® hydrophilic coating delivers a high-performance hydrophilic surface coating that ensures excellent lubricity, durability, and minimal particulate release, making it fully safe for clinical applications.

Wide Application Range

Ideal for hydrophilic coating catheters, including cardiovascular, neurovascular, urological catheters, stent delivery systems, and guide wires, providing smooth device navigation in complex vascular environments.

Enhanced Lubricity and Safety

This lubricious hydrophilic coating reduces friction and improves patient comfort, while the hydrophilic polymer coating technology maintains long-term water retention for optimal performance.

Versatile Coating Methods

The uv cure hydrophilic process allows precise application on various device surfaces, producing uniform, thin, and durable hydrophilic coatings for medical devices.

Product Advantages

Optimal Lubricity and Durability

The jAqua® lubricious hydrophilic coating achieves a perfect balance between lubricity and durability through precise parametric adjustments, ensuring smooth navigation in complex vasculature while maintaining structural integrity.

Low Particulate Release

As a hydrophilic coating for medical devices, it minimizes leaching and maintains a uniform, transparent appearance, providing reliable performance for sensitive medical applications.

Flexibility and Softness

This hydrophilic polymer coating exhibits excellent rebound and flexibility, allowing the hydrophilic coating catheter to bend through tortuous paths without cracking or delaminating, while preserving soft tips for patient safety.

Efficient UV Cure Process

The uv cure hydrophilic technology reduces curing time by over 80%, enhancing production efficiency while producing durable, long-lasting hydrophilic medical coatings.

Sterilization Compatibility

Compatible with ethylene oxide (EO) and electron beam sterilization, ensuring safe clinical use.

Overall, jAqua® offers an advanced hydrophilic surface coating solution combining superior lubricity, flexibility, and production efficiency.

Scroll down to learn more about jAqua® Hydrophilic Lubricious Coating.

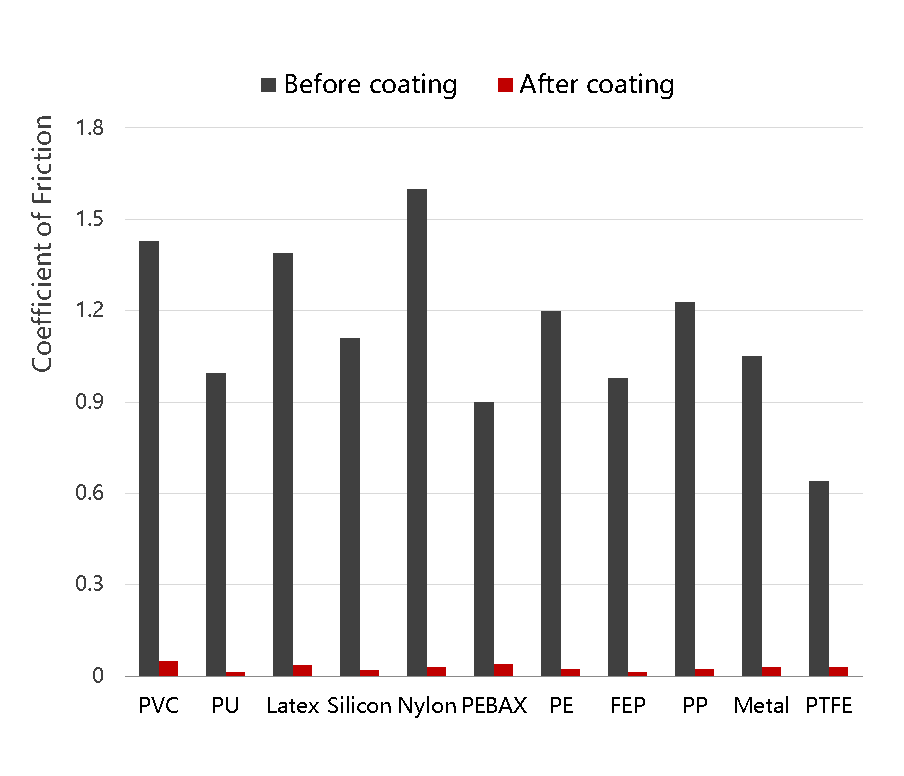

Friction Test

The Coefficient of Frictions of various substrates are reduced by more than 95% with the application of hydrophilic coatings.

Coefficient of Frictions before and after applying hydrophilic coating on different substrates.

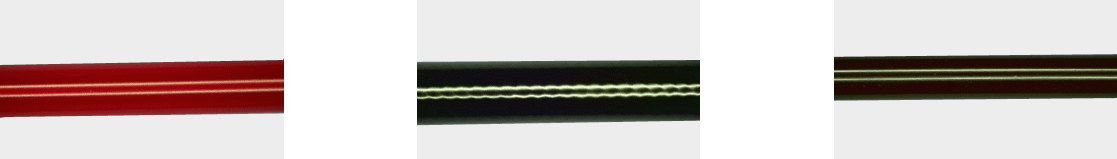

Upon microscopic observation, the surfaces of hydrophilic coated products were found to be even and uniform.

The application of metallic devices

The jAqua® lubricious hydrophilic coating delivers superior hydrophilic coatings for medical devices, offering excellent lubricity, durability, uniform appearance, and flexibility when applied to metallic components.

Even after 25-50 cycles of friction testing, the hydrophilic surface coating maintains its low coefficient of friction and intact appearance, highlighting the robustness and long-lasting performance of this hydrophilic polymer coating.

This UV cure hydrophilic technology ensures consistent quality and reliable results, making it an ideal hydrophilic coating catheter solution for demanding medical applications.

The application on braided tubes

The intricate structure of braided tubes presents challenges for hydrophilic coatings, as detachment can occur during use. jMedtech provides an advanced lubricious hydrophilic coating solution that enhances the surface hardness of braided tubes without affecting their performance.

This hydrophilic surface coating achieves a reduction in the coefficient of friction by over 95%, while coated samples demonstrate excellent microparticle stability, chemical properties, and biocompatibility. The hydrophilic polymer coating technology ensures consistent and reliable performance, making jAqua® hydrophilic coatings for medical device ideal for hydrophilic coating catheter applications.

Applications

Technical Resources

Download more information on how our jAqua® Hydrophilic Lubricious Coating and expertise can tackle unmet needs.