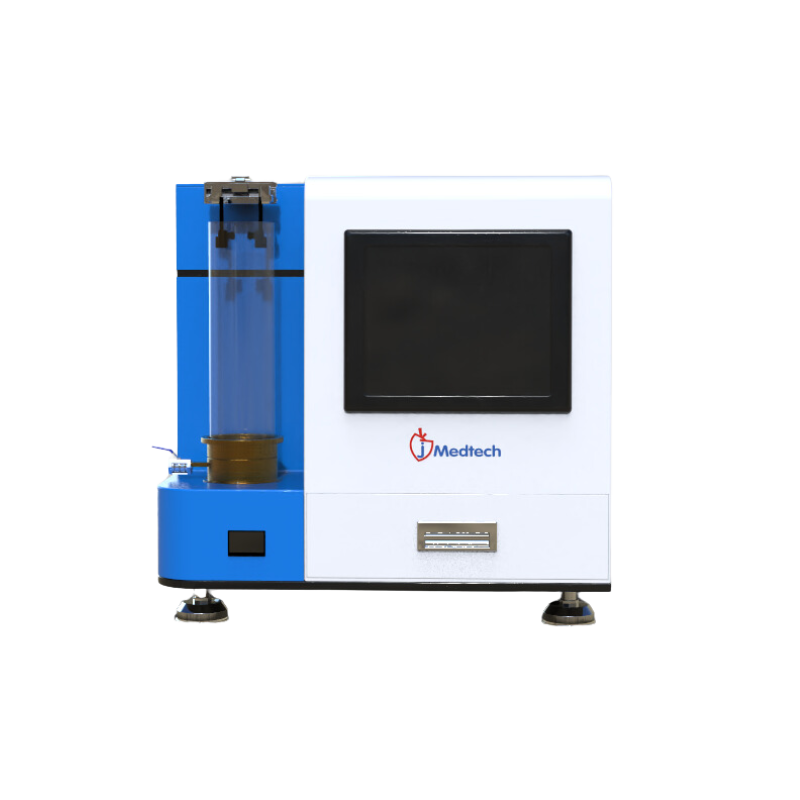

Coating Equipment

At jMedtech, we provide state-of-the-art coating machines and coating testing services designed for hydrophilic medical device coating and other surfacing coating medical device applications. As a trusted coating machine manufacturer, our equipment ensures high efficiency, precision, and reliability for diverse production and testing needs.

Hydrophilic Coating Machines:

Fully automatic catheter coating machines capable of UV curing, achieving an annual production capacity of 150,000–200,000 units with only 1–2 operators. Features include five-stage variable lifting speed to ensure uniform coating and imported Dymax UV curing modules.

Integrated Circular Coating Production Lines:

Includes automatic lines for balloon hydrophilic coating, guidewire continuous coating, urinary catheter coating, and flexible guidewire/catheter coating. The modular, circular design allows for fully automated batch production with an hourly output of nearly 1,000 units. Anti-tangling features and automated product entry detection ensure consistent quality.

Friction Coefficient Testing Equipment:

Available in vertical and desktop models, compliant with YY/T1898-2024. Force range: 0–2000g (0–20N); module stroke: vertical 0–700mm, desktop 0–300mm (customizable for extended ranges). High-precision controller drive guarantees accurate coating performance testing and automatic report generation.

Why Choose jMedtech Coating Equipment

Our solutions empower manufacturers to achieve superior hydrophilic coating quality, reduce friction, and optimize production efficiency. From automatic coating systems to coating performance testing, jMedtech is your reliable partner for precise, high-performance catheter coating and medical device production.

If you have any questions about equipment selection, feel free to contact jMedtech for expert guidance.