Product Introduction

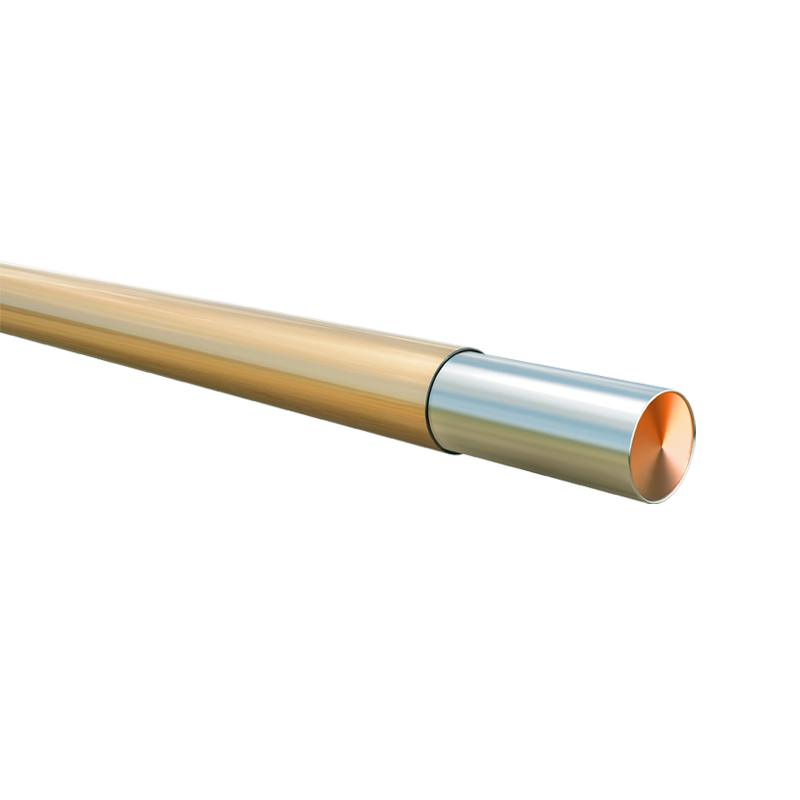

The Dip Coating process enables the production of thinner PTFE liners with strong surface adhesion through a thin thermoplastic outer layer. This advanced method also ensures isotropic properties by preventing molecular orientation within individual PTFE chains. As a result, jMedtech’s MorphoLiner™ OTW design provides reliable PTFE catheter liners that combine the benefits of thin wall medical tubing with the durability of high-performance PTFE medical tubing. With smooth PTFE lining and enhanced flexibility, it is an ideal solution for medical applications requiring flexible PTFE tubing.

Product Advantages

Ultra-Thin Wall Thickness

The jMedtech MorphoLiner™ Casted OTW PTFE liner features an ultra-thin wall thickness of just 0.0003 inches (approximately 7.62 microns). This medical PTFE thin-walled tube structure enhances softness and transparency, reducing catheter diameter. Its ultra-thin design improves lubricity, minimizing irritation and potential damage to surrounding tissues during insertion or withdrawal of medical instruments.

Industry-Leading Tolerance

Each PTFE catheter liner undergoes rigorous testing to ensure unmatched precision and quality. Strict inspections control the inner diameter tolerance within ±0.0003 inches and the wall thickness within ±0.0001 inches, demonstrating the reliability of thin wall medical tubing for demanding clinical applications.

Production Consistency

MorphoLiner™ production is based on a controlled Dip Coating process, with every stage meeting the highest standards to guarantee uniformity and reliability. This ensures a stable, high-quality component for the development and manufacture of advanced medical devices using PTFE medical tubing.

Quality Assurance

Produced in ISO 13485-certified cleanrooms, jMedtech MorphoLiner™ PTFE lining complies with biocompatibility requirements for medical devices. State-of-the-art equipment and precise measurement systems guarantee consistent product quality and performance.

After-Sales Service

jMedtech provides comprehensive after-sales service, ensuring a worry-free experience for customers choosing our PTFE medical tubing.

Support for Custom Sizes

MorphoLiner™ can be tailored to customer requirements. Whether you need flexible PTFE tubing or high-strength PTFE catheter liners, jMedtech delivers reliable solutions to meet your needs. This flexibility makes it suitable for a wide range of catheter and medical device applications.

Short Lead Time

With strong expertise in procurement, production, and sales, jMedtech shortens the delivery cycle significantly. Standard PTFE liners are available within 2 weeks, while customized sizes of PTFE tubing thin wall can typically be delivered within 4–8 weeks.

Application product type

jMedtech MorphoLiner™ Casted OTW PTFE liners, produced through the advanced Dip Coating process, are widely applied in medical devices that require reliable PTFE catheter liners and precision thin wall medical tubing. Their smooth PTFE lining and highly flexible PTFE tubing structure make them ideal for a variety of catheter systems, including:

○ Microcatheters

○ Midline catheters

○ Mechanical thrombectomy catheters

○ Guide catheters

○ Support catheters

○ Adjustable catheters

○ Suction catheters

○ Other catheters

If you are unsure whether it is suitable for your application, please feel free to contact us.