jMedtech is a pioneer in ultra-thin walled medical liner production and one of the first in the world to master both the free extrusion and extrusion over-the-wire liner with mandrel technologies.

Product Introduction

The MatrixLiner® OTW PTFE Liner with Mandrel from jMedtech utilizes an exclusive PTFE lining process that integrates the core wire concept into the casting stage. This innovation enhances flexibility, achieving an ultra-thin custom PTFE tubing wall with minimal tolerances. By reducing device size, this approach enables extruded tubing for catheter designs to navigate even the most complex and tortuous vasculature systems. As a result, medical device engineers gain greater versatility when developing next-generation catheter liners and advanced medical polymer tubing for various polymer tubing medical devices.

Customized Features

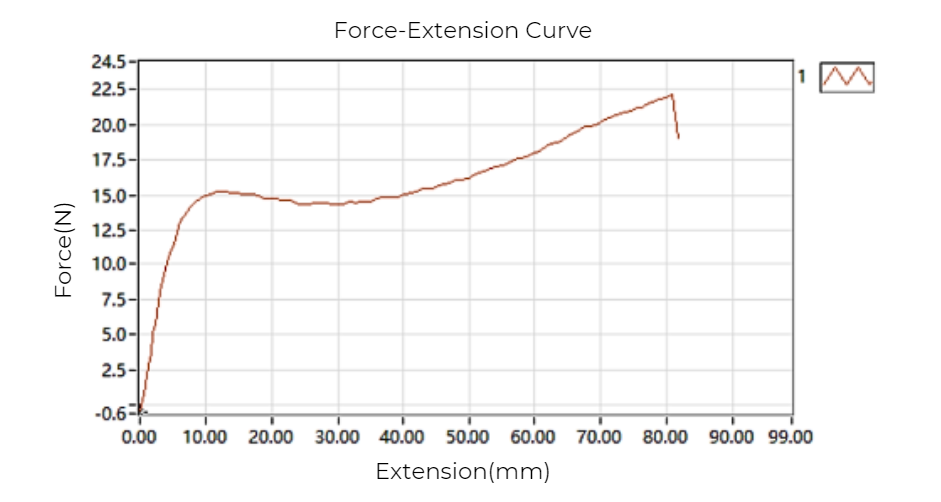

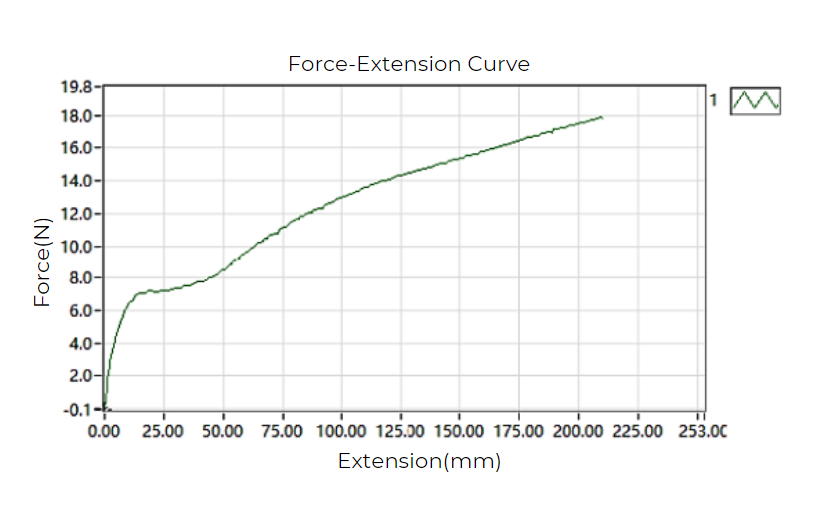

The MatrixLiner® Free Extruded Liner offers customizable options, including ToughFlex™ (TF) for high yield strength and ElastiFlex™ (EF) for high elasticity, providing enhanced flexibility to meet specific application needs.

(ToughFlex™ Force/Extension>0.65 )

(ToughFlex™ Force/Extension>0.65 ) (ElastiFlex™ Elasticity≥800%)

(ElastiFlex™ Elasticity≥800%)Product Advantages

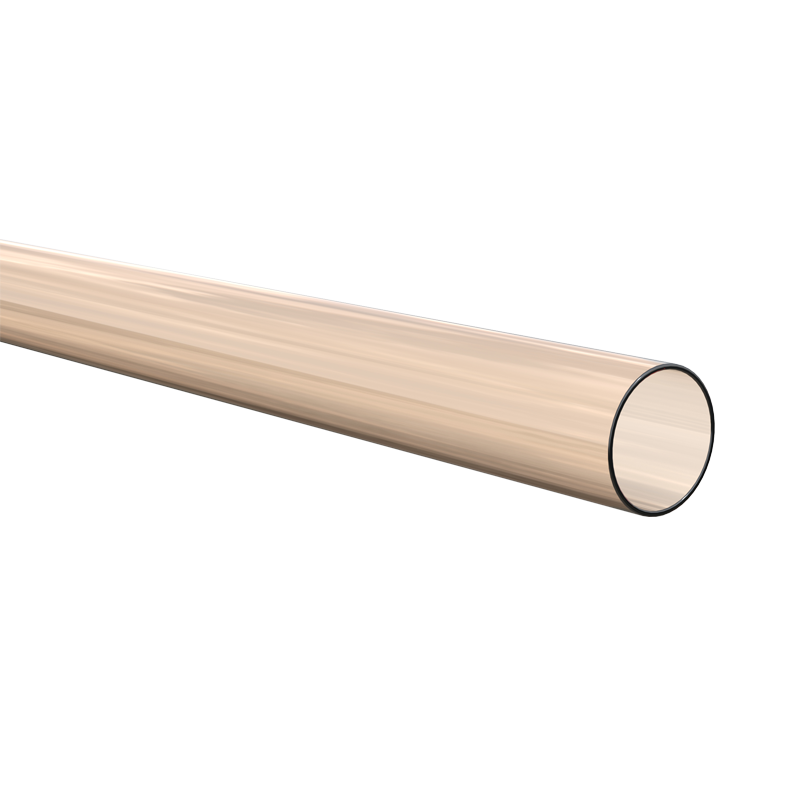

Ultra-Thin Wall Thickness

The MatrixLiner® PTFE liner from jMedtech achieves an ultra-thin wall thickness of up to 0.0005 inches (approximately 12 microns). This PTFE lining process enhances material softness and transparency, reducing catheter diameter. The ultra-thin design improves lubricity, minimizing tissue damage and irritation during insertion and withdrawal of medical instruments, making it an ideal choice as extruded tubing for catheter and other medical polymer tubing applications.

Industry-Leading Tolerance

Each MatrixLiner® custom PTFE tubing undergoes rigorous inspection to ensure precision and quality. Strict controls maintain the inner diameter within ±0.0005 inches and wall thickness within ±0.00025 inches, providing confidence for catheter liners and ptfe liner applications in advanced medical devices.

Production Consistency

MatrixLiner® production follows a standardized process—including extrusion, cutting, winding, and other steps—adhering to strict standards to guarantee uniformity and reliability. This ensures stable, high-performance components for extruded tubing medical and custom PTFE tubing used in research, development, and production of polymer tubing medical devices.

Excellent Tensile Strength

MatrixLiner® demonstrates superior tensile strength compared to similar PTFE liner applications, offering durability and confidence in long-term performance.

After-Sales Service

jMedtech provides impeccable after-sales service, ensuring a worry-free purchase and reliable support.

Support for Custom Sizes

MatrixLiner® can be tailored to specific requirements, ensuring a precise fit for custom PTFE tubing, catheter liners, and medical device products. This flexibility enhances reliability, operability, and overall performance.

Short Lead Time

Leveraging strong procurement, production, and supply chain capabilities, jMedtech significantly reduces delivery times. Standard products are ready within 2 weeks, while custom sizes are delivered within 4–8 weeks.

Application product type

MatrixLiner® OTW PTFE Liner from jMedtech are utilized in a wide range of ptfe liner applications and custom PTFE tubing solutions. Typical product applications include:

Microcatheters

Midline catheters

Mechanical thrombectomy catheters

Guide catheters

Support catheters

Adjustable catheters

Suction catheters

Other specialized catheters

These extruded tubing for catheter and medical polymer tubing solutions provide consistent quality and reliability for advanced catheter liners and other polymer tubing medical devices, supporting precise and high-performance medical device development.

If you are unsure whether this product fits your application, you can contact our specialists for professional guidance.

Product Parameters

Technical Resources

Download more information on how our MatrixLiner® PTFE Extruded Liner and expertise can tackle unmet needs.