jMedtech Chief Scientist Dr Gregory Teh had the privilege of being interviewed by PlasticsToday to discuss how microextrusion and advanced materials are transforming catheter design for the future of minimally invasive procedures.

Platics Today, as a derivative brand of the nearly 100 year old American journal Modern Plastics, focuses on the latest developments in plastic processing and materials technology, industry trends, and predictions for future development. It is one of the leading authoritative publications in the plastic industry.

From ultra-thin liners that enhance flexibility to reinforced structures improving pushability and kink resistance, these innovations are enabling more precise, reliable, and effective medical devices.

Catheter liners play a foundational role in the performance of minimally invasive medical devices, noted Teh. The thin-walled, high-precision components act as inner layers within catheters, providing essential properties such as lubricity, structural integrity, and biocompatibility. “Their function is particularly crucial in neurovascular and cardiovascular interventions, where the precision of guidewire tracking and catheter flexibility determines the success of complex procedures,” said Teh.

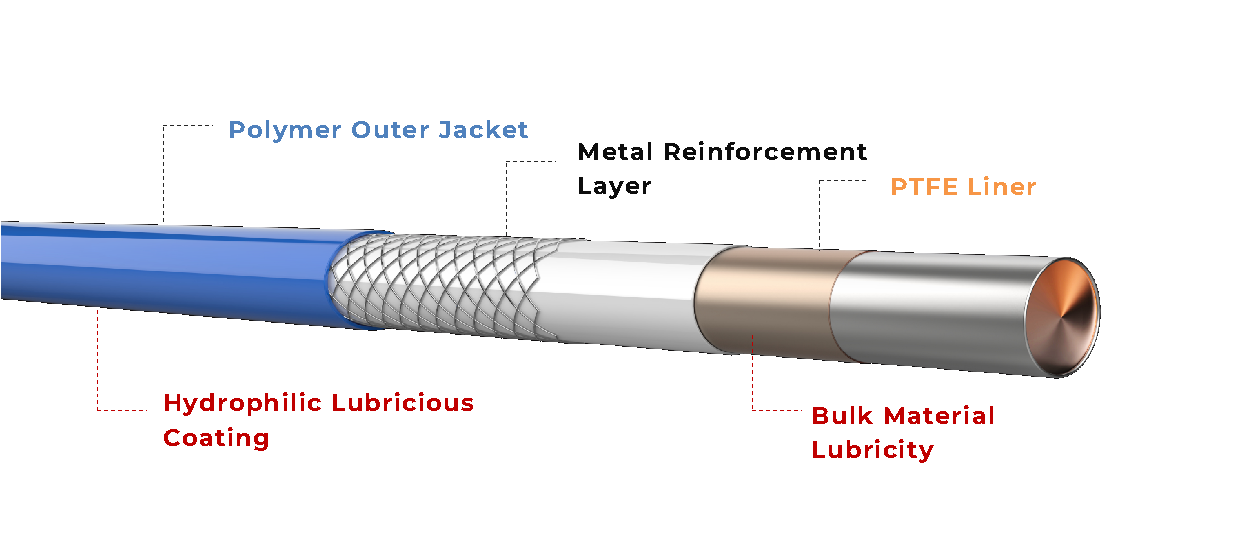

Components of a typical catheter build, with hydrophilic coating providing lubricity through surface modification and PTFE liner requiring innovations in microextrusion

Components of a typical catheter build, with hydrophilic coating providing lubricity through surface modification and PTFE liner requiring innovations in microextrusion

Innovations in microextrusion, material processing, and surface modification have allowed for the development of ultra-thin, high-strength, and chemically resistant liners that enhance procedural efficiency and patient safety.

According to Teh. “Reduced trauma and vascular injury is one of the key benefits, as low-friction liners significantly minimize resistance during catheter insertion. This reduces mechanical stress on delicate blood vessels, lowering the risk of endothelial damage, which can lead to serious complications such as thrombosis or restenosis.”

oreover, precision liners that enhance guidewire and catheter navigation have improved procedural success rates. “This is particularly critical in complex procedures such as stroke interventions, cardiac ablations, and stent placements, where even minor resistance or misalignment can compromise patient outcomes.”

Faster recovery times are enabled by the use of more flexible, biocompatible liners that reduce post-procedure complications. “With less friction and improved manoeuvrability, these liners help minimize inflammation, infection risks, and procedural discomfort, leading to shorter hospital stays and better overall patient experiences,” said Teh.

The durability and chemical resistance of catheter liners play a crucial role in ensuring long-term safety in implanted devices, according to Teh. “Advanced liners prevent material degradation and leaching, which is essential for maintaining the performance of chronic catheterization devices and controlled drug delivery systems. By enhancing both the short-term and long-term outcomes of catheter-based interventions, these innovations are significantly improving patient care and procedural efficiency.”

Accuracy in catheter liner production has benefited immensely from modern microextrusion closed-loop feedback systems, said Teh. “The systems allow for extreme precision in dimensional tolerances, making it possible to produce ultra-thin catheter liners with wall thicknesses as low as 0.0005 in. (12.7µm). These developments are particularly critical in neurovascular and cardiac interventions, where device performance directly impacts patien.

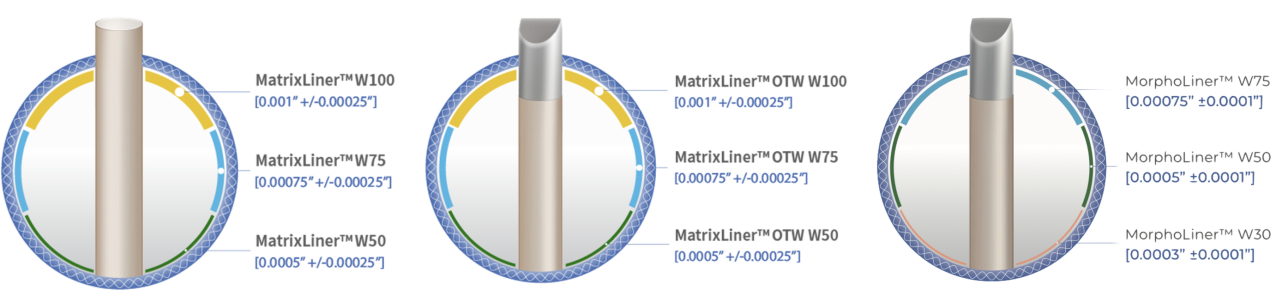

jMedtech’s PTFE liner product series, encompassing liners produced by various techniques to achieve ultra-thin wall thicknesses with customizable strength and flexibility.

jMedtech has developed microextruded PTFE liners achieving tolerances of ±0.00025 inches (±6.35 µm). These extremely tight tolerances are made possible with recent improvements in die designs.

Advances in materials, notably the development of bioresorbable polymers, has expanded the potential applications of catheter liners, according to Teh. “PLA-based bioabsorbable liners are being researched for applications in drug-eluting stents and post-surgical catheters, for example. These liners gradually degrade within the body, eliminating the need for device removal and reducing long-term risks associated with permanent implants. This innovation is particularly beneficial for pediatric patients or cases where long-term implantation is undesirable.”

A third area of innovation is in surface modification, which plays a crucial role in improving lubricity, biocompatibility, and hemocompatibility of catheter liners.

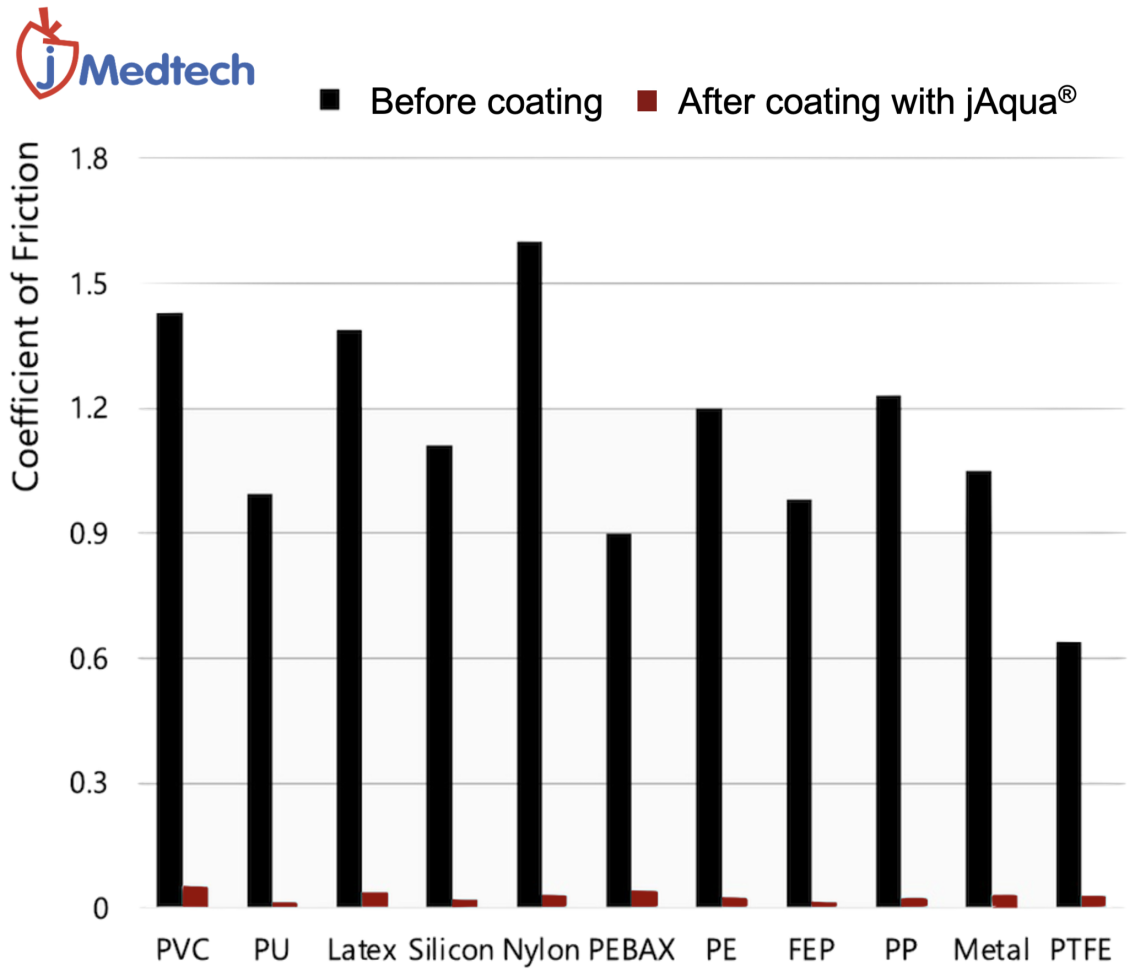

Coefficient of Frictions for various substrate materials are reduced by more than 95% upon coating with jMedtech’s jAqua® hydrophilic coating

These advances in materials and microextrusion technology also bring a set of challenges that, said Teh, industry overcomes through ingenuity and rigor. Processability is one example.

Dr Gregory Teh also mentioned“While high-performance polymers like PTFE and PEEK offer superior lubricity and biocompatibility, they are notoriously difficult to extrude because of their high melting points and viscosity. Achieving consistent crystalline structures is essential to maintain uniform mechanical properties across the entire length of the catheter. Inconsistent processing can lead to defects such as rough surfaces, voids, or dimensional instability, which can compromise catheter performance.”

For example,Multi-lumen catheters are also subject to manufacturing challenges, notably in terms of lumen collapse, ovalization, or concentricity issues caused by external forces and material shrinkage during the microextrusion process. “This is especially problematic in asymmetrical designs, where precise lumen placement is critical for device functionality,” explained Teh. “For example, one manufacturer developing a multi-lumen electrophysiology catheter encountered significant deformation issues. By optimizing die geometry, extrusion speed, and cooling parameters, engineers successfully improved lumen integrity, achieving consistent cross-sectional geometry throughout the length of the catheter.”

Catheter liners require an ultra-smooth inner surface to minimize friction and facilitate smooth guidewire navigation. Even minor surface irregularities can lead to drag, wire kinking, or procedural failure. Maintaining this level of surface perfection without escalating production costs remains a major challenge, according to Teh. So, jMedtech is tackling and improving the precision of manufacturing to solve the above problems.

Dr Gregory Teh advocates harnessing AI to identify defects in real time.“Advanced AI-driven extrusion monitoring systems are now being employed to detect micro-defects in real time, thereby reducing liner rejections and improving overall manufacturing yield,” said Teh. “These systems utilize sophisticated process control and validation techniques, such as robotics, sensors, and visual systems, to monitor manufacturing process parameters in real time. They observe the ejection of products from extruders and inspect final products in microscopic detail, all of which contribute to reducing production costs.”

While AI-driven manufacturing is revolutionizing process efficiency, other technological trends evolving in parallel also are having a profound impact on the design, development, and fabrication of next-generation catheter liners. “The industry is moving toward accelerated prototyping in catheter innovations and developments, bioabsorbable liners, and sustainable materials, all of which are shaping the future of minimally invasive devices,” said Teh.

jMedtech R&D team continues to overcome the difficulties in material research and precision manufacturing, providing medical device companies with more and better medical coatings and medical tubing products. We also firmly believe that the application of our products will better benefit humanity.

Click on the original link to read