In the field of medical devices, the design and material selection of catheters are crucial to surgical success and patient safety, particularly in vascular interventional treatments. Beyond flexibility and pushability, catheters must possess sufficient strength to resist externally applied forces and prevent deformation or damage during operation. PTFE liner has emerged as a preferred material for medical catheter design due to its unique physical and chemical properties. Notably, the application of the free extrusion process has significantly enhanced the yield strength of PTFE liners, resulting in revolutionary improvements in the performance and reliability of medical catheters.

Part 1: Concept of Yield Strength

Yield strength refers to the maximum stress that a material can withstand before undergoing plastic deformation under external forces. It is a critical mechanical property, directly related to the stability and reliability of a catheter during use. Higher yield strength indicates that the material can endure greater stress without experiencing plastic failure, resulting in enhanced strength and stiffness.

Part 2: Free Extrusion Process: Molecular Orientation and Yield Strength

For PTFE liners, yield strength is influenced not only by the material's inherent properties but also significantly by the manufacturing process.

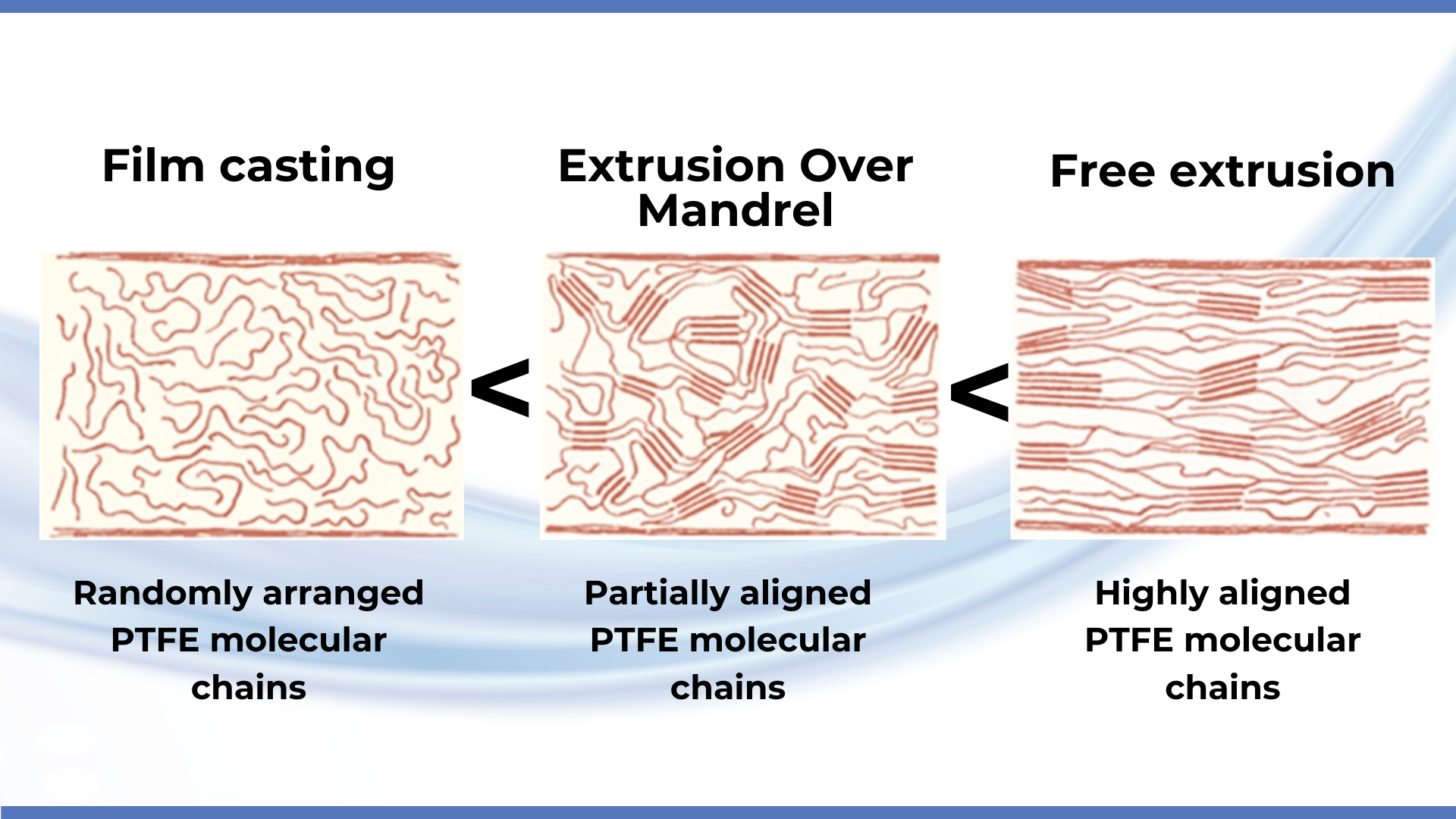

The primary manufacturing processes for ultra-thin-walled PTFE liners include film casting, free extrusion, and mandrel extrusion. Each production method results in different fibril molecular arrangements, leading to variations in the yield strength of the PTFE liners. Among these, the free extrusion process is particularly notable for optimizing molecular orientation, thereby enhancing the yield strength and overall performance of the PTFE liners.

As shown in the figure above, the fibril arrangement in the film casting process is random and disordered. In the extrusion over mandrel process, the fibrils are arranged more orderly to a certain extent. The free extrusion process, however, loosens the crystal grains in the PTFE matrix, allowing the fibrils to form along the axial or extrusion direction. This results in an orderly arrangement of PTFE molecular chains, enhancing the yield strength of the material.

Part 3: Enhancing Yield Strength

1. Production Process: Opt for Free Extrusion

As discussed previously, selecting the free extrusion process for producing PTFE liners typically results in higher yield stress due to the directional arrangement of molecular chains. This translates to significant performance advantages in medical device applications, particularly those requiring catheters to withstand substantial forces or navigate complex paths.

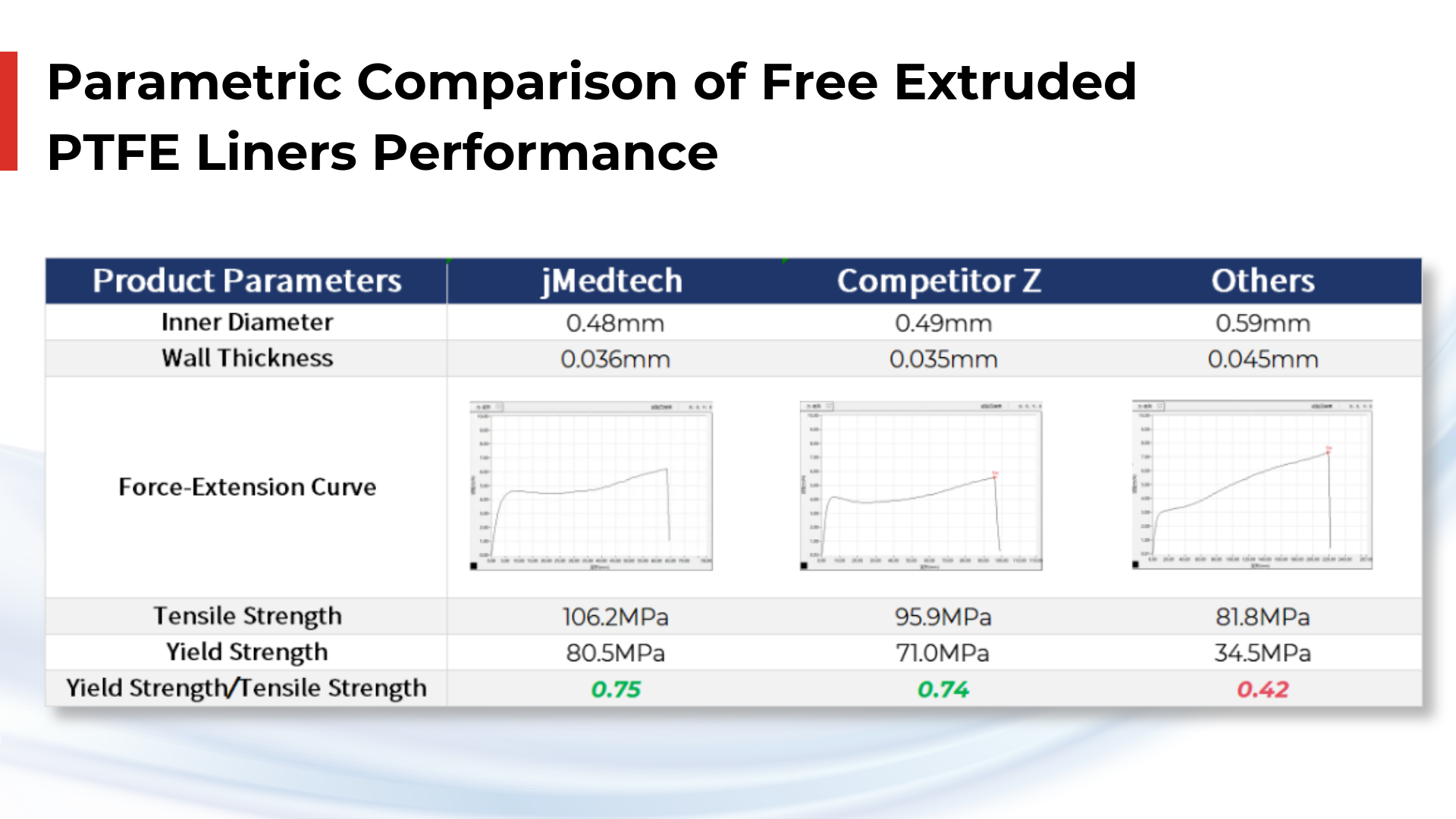

Thanks to its outstanding extrusion process, the MatrixLiner® free-extruded PTFE liner from jMedtech's subsidiary, jMedCath, demonstrates exceptional performance. Its yield strength, tensile strength, and other key properties can match or even surpass those of leading international brands in the industry, ensuring consistent quality and reliability.

2. Customized Solutions: Achieving the Perfect Balance of Wall Thickness and Yield Strength

2. Customized Solutions: Achieving the Perfect Balance of Wall Thickness and Yield Strength

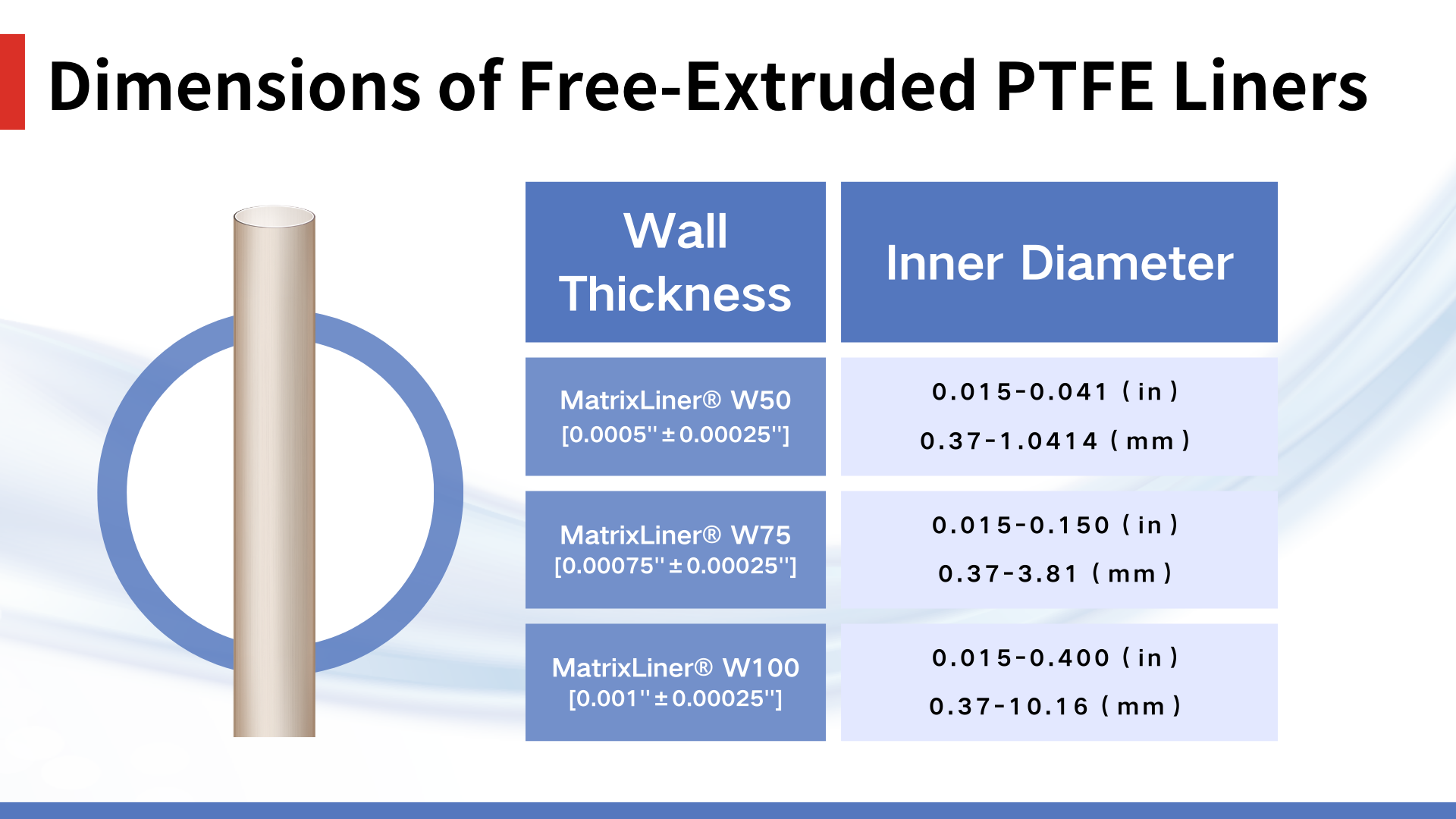

In addition to materials and manufacturing processes, the wall thickness of PTFE liners plays a crucial role in determining yield strength. However, the relationship between wall thickness and yield strength is not straightforward. While increasing wall thickness can enhance load-bearing capacity, it doesn't necessarily lead to proportional increases in yield strength. Moreover, excessive wall thickness may render the catheter overly rigid, compromising its flexibility and maneuverability.

Therefore, achieving optimal yield strength without significantly increasing stiffness requires careful optimization of wall thickness and other design parameters such as outer diameter and length.

With jMedCath's MatrixLiner® free-extruded PTFE liners, customization is key. Our technical team collaborates closely with customers to design and customize liners and catheters tailored to their specific requirements. Whether it's special sizes or specific properties, we ensure that PTFE liners with varying wall thicknesses meet expected yield stress levels, delivering the utmost performance and reliability.

In Summary

PTFE liners, manufactured through the free extrusion process, offer exceptional yield strength, making them highly suitable for various medical applications, including cardiovascular surgeries, minimally invasive procedures, and other precision-driven medical interventions.

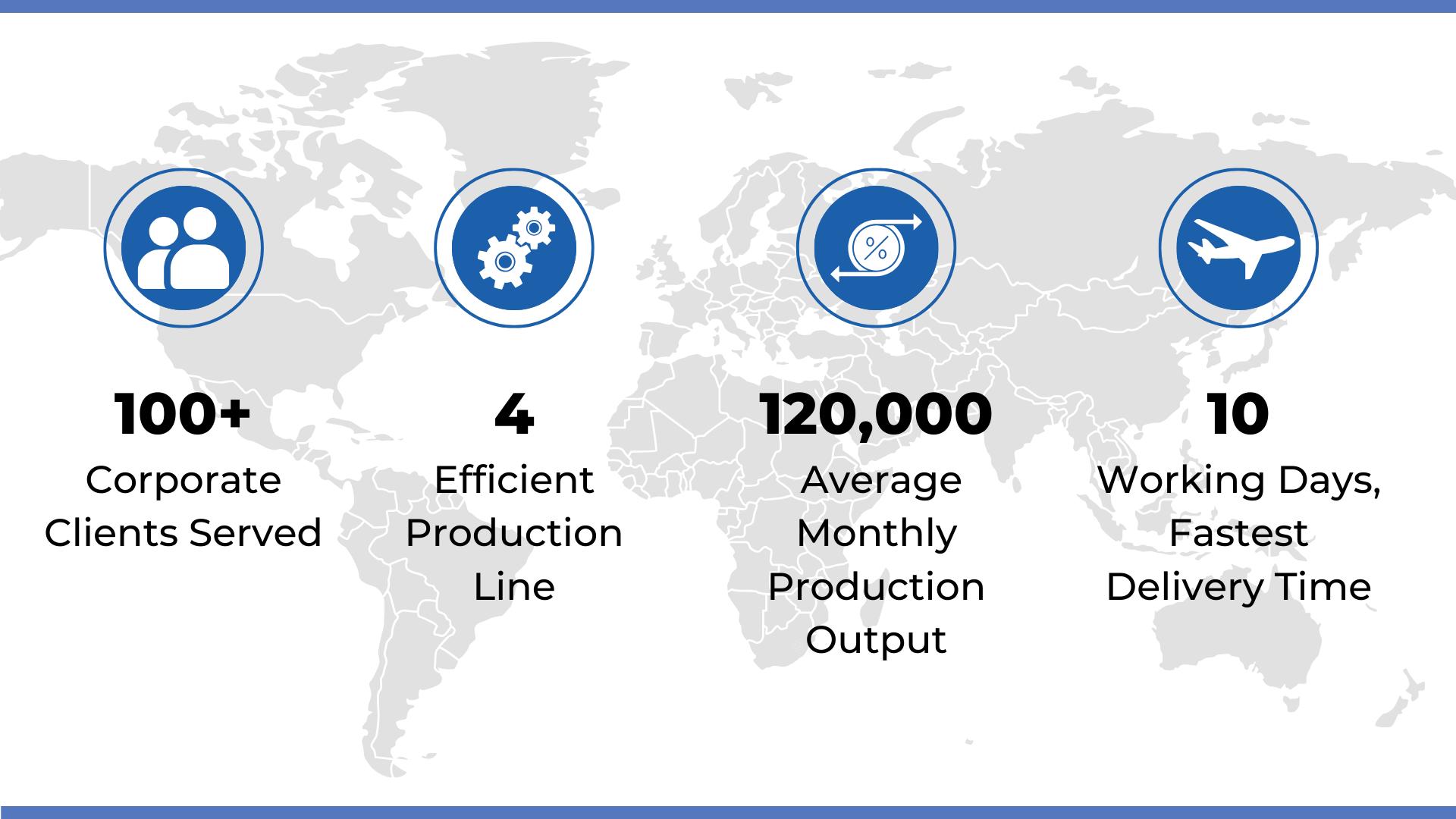

As a leading technology provider, jMedCath adheres rigorously to the ISO13485 quality management system, ensuring the delivery of high-quality free-extruded and mandrel-extruded PTFE liners for the medical device market. With a commitment to providing comprehensive solutions, jMedCath remains agile in responding to market demands, offering products with short delivery cycles (standard product delivery time of 2 weeks, customized product delivery time of 4-8 weeks).

If you're interested to learn more about PTFE Liners (mandrel extrusion/free extrusion), simply visit our website (jmedtech.com) to get in touch with us and receive complimentary samples.