In recent years, coatings have received a lot of attention in the medical device industry.Because the surface of the implanted device coated with the coating will be modified, it will have properties such as lubrication or anticoagulation, which will make the use effect of the medical device product and Competitiveness is enhanced. Therefore, various functional coatings are more and more widely used in medical devices.

Medical device companies apply a layer of functional coating to their products, which is a good idea to empower products and enhance product advantages. However, the cost of introducing the coating process may be relatively high for medical device manufacturers, not only need to purchase coating curing equipment, testing equipment, etc., but also need to train qualified technical operators and quality inspection personnel.

Therefore, to produce high-quality coated products under the premise of controlling input costs, and to ensure fast and stable delivery, it is necessary to choose an experienced coating OEM, which is crucial to ensuring product quality and project progress. important. Selecting a responsible and reliable supplier at the beginning of the project to avoid detours in the project is particularly critical in the current context of fierce competition in the medical device industry and projects racing against time.

jMedtech Coating has been focusing on medical functional coatings for more than 10 years. Since 2014, the company has built over 1,000 square meters of 10,000-class clean workshops, passed ISO: 13485 system certification, and the coating materials have good biocompatibility. The company mainly provides medical device customers with products and services such as coating OEM, coating solution supply, and coating supporting production and testing equipment. On the basis of guaranteeing product quality and delivery time, jMedtech Coating provides warm, honest and reliable services, and is the ideal and preferred coating OEM partner for customers.

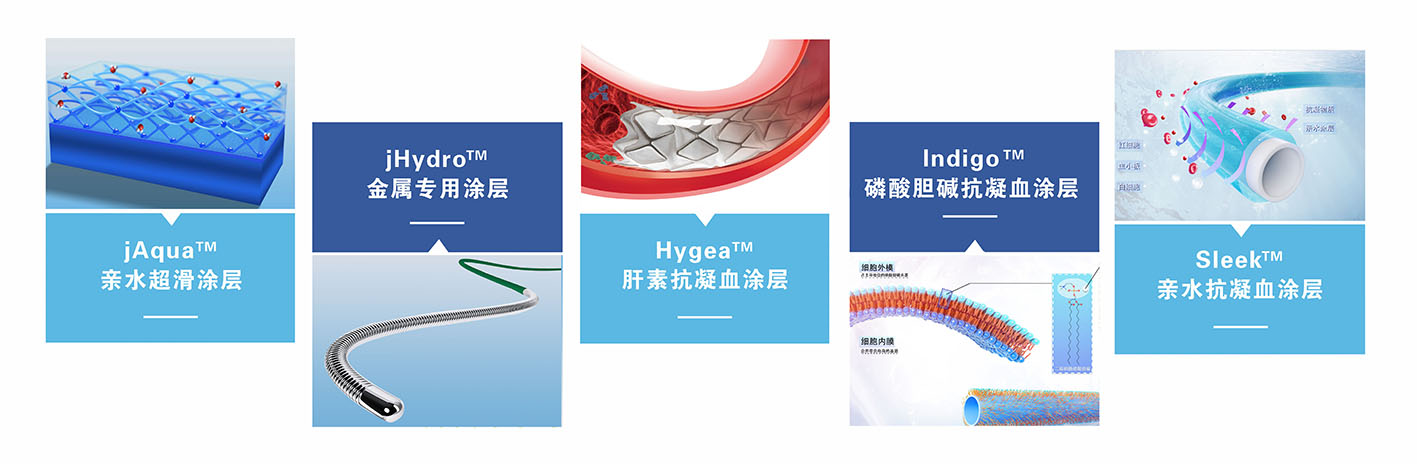

At present, the coating products supplied by jMedtech Coating include: hydrophilic super slippery coating, heparin anticoagulant coating, phosphorylcholine anticoagulant coating, and anti-crystallization coating, etc. jMedtech's hydrophilic super-slip coating has international patent protection and has been registered with the US FDA and the China Food and Drug Administration. The company's R&D team is still continuing to develop and test a variety of new coating products, which will be put into the market in the near future to serve a large number of medical device companies and help implant interventional surgery.

jMedtech's coating products have been clinically verified for many years, and their biocompatibility, safety, firmness and functionality have all been highly recognized by the market. According to incomplete statistics,As of the beginning of 2022, more than 50 million cardiovascular catheters have been coated with jMedtech. The company's products serve more than 300 domestic and foreign medical device companies, and have a high market share in the field of medical coatings. From the evaluation of product quality, stability, delivery cycle, and cost performance, jMedtech is the best choice for many listed medical device companies.

Products that can be processed with hydrophilic coatings include but are not limited to various catheters such as vascular intervention, nerve intervention, balloon catheters, urinary catheters, digestive catheters, and various guide wires.

Anticoagulant coating products include, but are not limited to, covered stents, dense mesh stents, artificial blood vessels, nerve interventional catheter guide wires, balloon catheters, metal implants, guide sheaths, central venous catheters, hemodialysis Tubes and other products.

The products of jMedtech coating are independently developed by the company's Singapore R&D team. The technical team has rich experience in the fields of medical devices, polymers, biomaterials, etc. jMedtech technical team can provide customers with all-round technical support from product registration materials, coating use training, coating production line construction, after-sales service, etc.

jMedtech has an experienced R&D technical team, production operation team, quality inspection team, and customer service team. The OEM process strictly implements the ISO13485 system process to eliminate any unstable behaviors and processes, while ensuring product traceability. In addition to the use of high-quality coating materials, the technical and production personnel of jMedtech workshop have passed strict production quality training, have rich production experience, and can skillfully and quickly operate the coating coating process to ensure the perfection of products and coatings combined.

From raw material to product shipment, jMedtech coating OEM project has a mature and complete system process. Focusing on medical functional coatings, we always insist on providing customers with the highest quality coating products. This is our obligation and our mission.

The delivery cycle of coating OEM products is stable and guaranteed. The workshop has multiple OEM product lines, and the delivery cycle is short. And regularly follow up customer feedback and provide comprehensive after-sales service.

For detailed coating processing or other coating cooperation matters, please contact jMedtech Coating. Our professional sales representatives will provide you with service and answer your inquiries.

(jMedtech coating main business: hydrophilic super slippery coating (hydrophilic coating), anti-coagulation coating, antibacterial coating, hydrophilic coating equipment, friction testing equipment and coating processing services, etc.)