The physical properties of the hydrophilic coating of disposable medical interventional catheters are usually evaluated from two aspects: lubricity and firmness. The general test method is as follows:

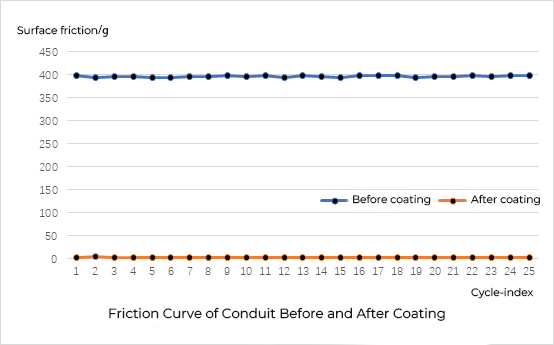

The hydrophilic coating sample catheter to be tested is first soaked in a constant temperature water bath for 30-60 seconds. After fully soaking, set a clamping force of 300g on the catheter through a friction device, and pull it 25 times in a cycle. During this process, the friction test The instrument will display the real-time data of catheter friction, and record the friction-displacement curve, and automatically generate a data table through the program.

Analyze and compare the average friction force of each cycle of the test catheter from the friction force-displacement curve, and the lower the friction force, the better the lubricity of the coating.

From the analysis of the friction force-displacement curve, if the friction force curve of 25 times does not have an obvious upward trend, it indicates that the friction force of the coating is not easy to fall off after repeated friction.

Comparison table of average friction value of 25 cycles:

| sample | 25 cycle average friction force/g |

|---|---|

| Uncoated conduit | 397.0 |

| Gemite jAqua TM hydrophilic coating catheter | 3.3 |

The average friction data showed that the friction of the catheter with jAqua TM hydrophilic coating was reduced to 3.3 g, which is 0.76% of the friction of the uncoated catheter, indicating that the hydrophilic coating has significant lubricity Effect.

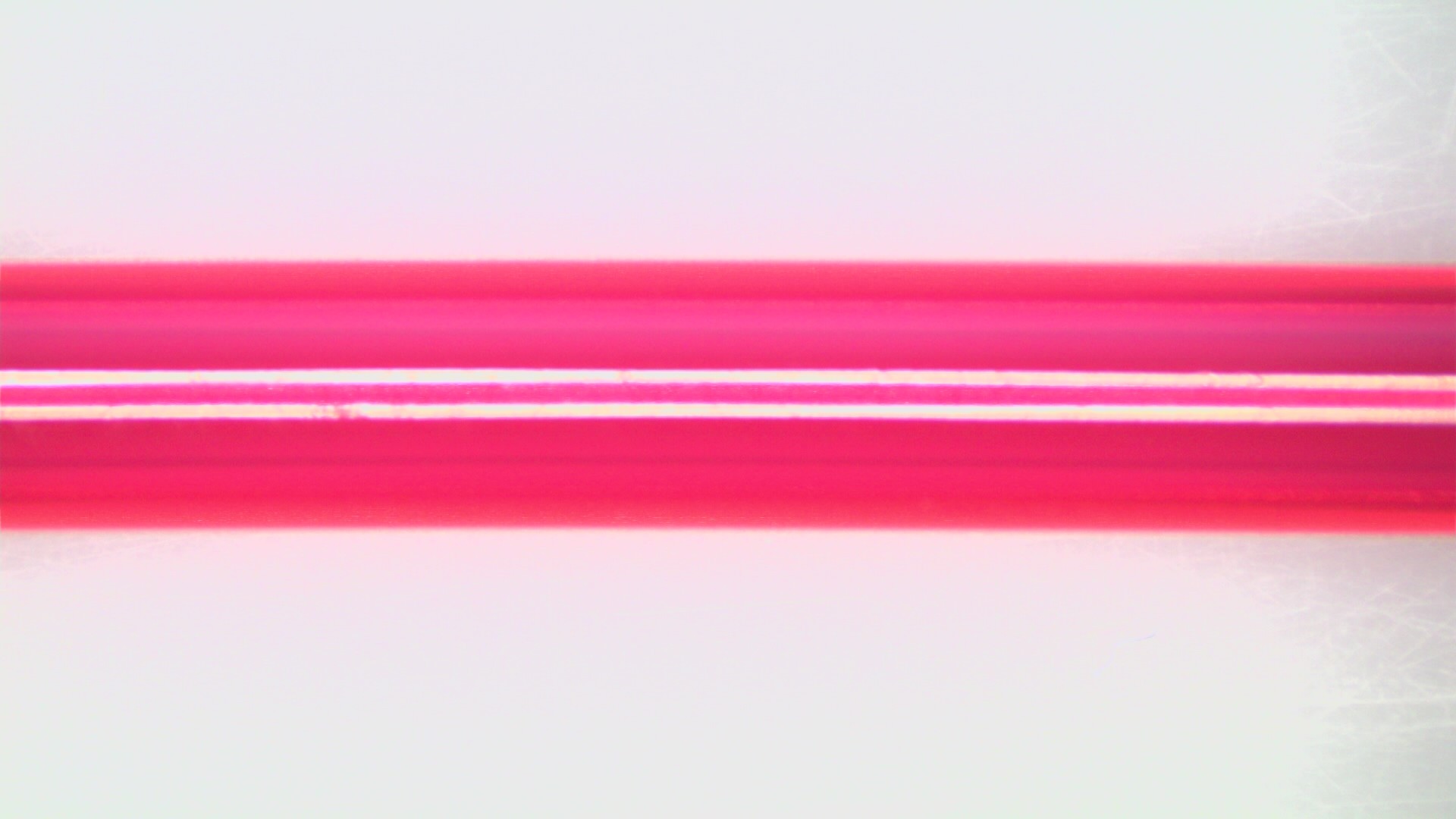

The hydrophilic coating coated on the catheter is generally colorless and transparent, and the thickness of the coating is very thin. The cured coating cannot be directly observed with the naked eye to judge its coating effect.

In order to better observe the coating effect, soak the coated catheter after the friction test in the Congo red solution, and use the principle of specific adsorption between the Congo red and the polyvinylpyrrolidone in the coating to make the coated catheter The area will be stained red.

After the test section is dyed, the coating is evenly colored, and if there is no red area, it is judged as qualified;

When there is an uncolored area in the test section, if there is only one uncolored area and the length does not exceed 1mm, it is judged as qualified;

There is only one uncolored but the length exceeds 1mm, or there are many uncolored coatings, it is judged as unqualified.

It can be seen from the figure that the surface of the catheter is stained evenly, and there is no uncolored phenomenon, indicating that the tightness of the bonding between the hydrophilic coating and the surface of the catheter substrate is high, that is, firm Strong.

The above are the reference steps and precautions for judging the effect of the hydrophilic coating.

The above standards refer to the "Standard Method for Performance Evaluation of Hydrophilic Coatings of Disposable Medical Vascular Intervention Catheters". For details, please contact: 18250760617