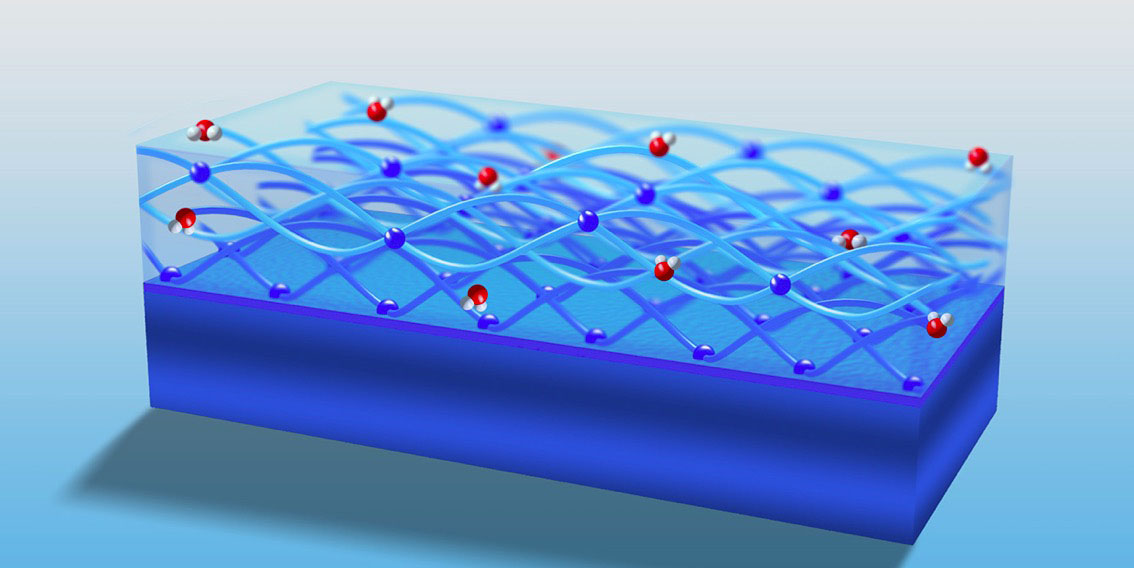

Hydrophilic coating is a mixture that can be applied to medical devices to modify their surface to achieve hydrophilic lubrication. In the coating production process, in order to achieve the ideal effect, it is necessary to ensure that the coating quality during production is good and meets the production standards.

The stability of the coating directly affects the performance of the product. After opening, the coating may change some parameters of the coating due to exposure to air, so its storage and use will directly affect the cost of the coating. So how to choose a more suitable coating solution from the storage conditions of the coating?

1. The storage conditions of the hydrophilic coating solution, do you need special temperature and humidity for storage and handling? Is it necessary to store at low temperature?

2. Is the hydrophilic coating solution used after opening the cap not required to be stored overnight or discarded within 48-72 hours? How to define the validity period of the solution after opening the cap?

3. Will there be sediment in the unused hydrophilic coating solution after opening the cap?

The hydrophilic coating produced and sold by jMedtech has strong stability and no sediment. Therefore, as long as the correct storage work is done, the quality of the coating can be maintained for a longer time after opening, and the coating can be reduced to a certain extent. layer solution loss. Under the condition of proper storage of jMedtech hydrophilic coating, guarantee that the coating viscosity is controlled within the standard range, can be used repeatedly for a long time to produce high-quality hydrophilic coating devices.

The basis for directly judging whether the hydrophilic coating solution can continue to be used is the viscosity of the coating solution, if If the viscosity of the solution changes more than a certain value, it means that the quality of the solution may be damaged, and the product produced at this time will affect its quality and pass rate. Therefore, When we save the hydrophilic coating solution, we must consider various factors that affect the viscosity of the coating . Through the research and development tests of Gemate coating engineers, the following points need to be done to store the solution reasonably.

UV-cured coating solutions also contain reactive chemicals that polymerize under the action of light and heat, causing the viscosity of the coating solution to rise. Therefore, the hydrophilic coating solution should be packaged in a light-proof container, and should be protected from ultraviolet light during use and transfer.

At the same time, due to the chemical activity of the hydrophilic coating solution, the container used for storage must be non-reactive to ensure that no other impurities are introduced. HDPE or glass containers are recommended here.

The factor that has the greatest influence on the viscosity of the hydrophilic coating solution is the volatilization of the main solvent, and the increase in the viscosity of the solvent volatilization solution leads to poor coating effect. In order to prevent the solvent from volatilizing, it is necessary to pay attention to sealing/room temperature/room temperature away from light during storage.

The solution can also be stored at a low temperature of 2-8 °C, but in the case of low temperature storage, the solution needs to be taken out of the low temperature environment before each use, and placed at room temperature for 30 minutes to 1 hour to return to room temperature before opening the bottle cap for use .

Considering various factors, when storing the hydrophilic coating solution, you need to pay attention to seal, avoid light, avoid high temperature, so as to reduce solvent volatilization, in addition, need to use inert material container to hold the solution to avoid the solution and The container reacts, changing the original properties of the solution.

For detailed solutions of hydrophilic coating solutions, you can consult Gemtech Coating.

(The main business of jMedtech Coating: hydrophilic coating, anti-coagulation coating, hydrophilic coating for metal layers, hydrophilic coating equipment, friction testing equipment, etc.)