Interventional therapy is a new type of high-tech minimally invasive treatment technology in modern medicine. It has the characteristics of small trauma, multiple indications, definite curative effect, and fast postoperative recovery. It is an important development trend of future medicine.

Among them, the interventional catheter plays a vital role in the operation. Since the outer polymer materials of the interventional catheter are mostly hydrophobic, such as polyurethane (TPU), polyetheramide (Pebax) and nylon (PA), this Such materials have high friction, which will cause varying degrees of damage to human tissues and blood vessels. However, coating the surface of medical catheters with a hydrophilic coating can effectively reduce their surface friction, thereby reducing damage to the human body.

Therefore, it is very necessary to apply a hydrophilic coating on the surface of catheters and guide wires for interventional therapy.

Founded in 2013, jMedtech Coating is the first company in China to independently develop and produce medical hydrophilic super-slip coatings, breaking the monopoly of foreign hydrophilic coating markets, and providing new medical device manufacturers at home and abroad. A reliable choice.

In 2014, jMedtech Coating signed a strategic partnership with the Singapore Research Agency (A*Star), established partnerships with world-class universities such as the National University of Singapore and Nanyang Technological University, and independently developed hydrophilic coatings to inhibit thrombosis Heparin anticoagulant coating, holds patents for self-developed hydrophilic coating and anticoagulant coating.

In 2017, jMedtech's Hydrophilic Lubricious Coating completed the US FDA filing.

Up to now, more than 50 million cardiovascular catheters have used jMedtech's hydrophilic super-slip coating. The domestic market share of hydrophilic coatings exceeds 80%. Most of the cooperative customers are large-scale listed medical device manufacturers.

Lubricity is a surface characteristic of a material, measured by the magnitude of the surface friction coefficient.

The hydrophilic coating has the characteristics of affinity for water, and the negative charge of the coating will combine with the dynamic hydrogen bonds in the water, which helps the mutual integration of the coating and the aqueous solution.

The physical interaction between the coating and water forms a gel material that exhibits an extremely low coefficient of friction, thereby changing the surface properties of the catheter to achieve a lubricating effect.

The lubricating surface of the catheter with a hydrophilic coating on the surface reduces the intervention force, which makes it easier for the device to penetrate the blood vessel, avoiding possible human blood vessel puncture and tissue friction damage.

From the friction test chart, it can be seen that after 25 round-trip frictions, the friction force of the guide wire with hydrophilic coating is uniform and stable.

It can be seen from this that the jMedtech hydrophilic coating will not easily fall off from the surface of the guide wire, and has relatively good firmness and stability.

This means that the hydrophilic coating will not fall off due to friction during normal operation, resulting in increased catheter friction or residues left in human tissue, with a high safety factor.

The surface of the catheter with jMedtech hydrophilic coating is smooth and uniform, without grain feeling, and the attached hydrophilic coating can be evenly dispersed on the surface of the catheter, which makes the hydrophilic coated catheter more lubricated.

jMedtech hydrophilic coating uses PVP as the substrate, and PVP is a synthetic water-soluble polymer compound, which has the general properties of water-soluble polymer compounds.

The excellent physiological inertia of PVP makes it not participate in the metabolism of the human body, has excellent biocompatibility, and does not cause any irritation to the skin, mucous membranes, eyes, etc. PVP can also be used as a coloring agent and X-ray contrast agent; it can be used in various dosage forms such as tablets, granules, and water preparations. It is a substance that has been widely used and verified for safety.

jMedtech's hydrophilic super-slip coating has been verified for safety and stability in clinical applications at home and abroad. Compared with hydrophilic coatings on other raw material substrates on the market, jMedtech's hydrophilic coatings have better biocompatibility.

jMedtech Coating is the first high-precision professional enterprise in China that independently develops and produces hydrophilic super-slip coatings. The links from product development and production to after-sales service are very mature. It has a precise and streamlined production line and a professional scientific research team. A business department that answers questions at any time, efficient and responsible after-sales service, etc.

Committed to providing satisfactory service to every customer is our purpose and original intention.

The clean production workshop of Jiemet coating is 10,000-level. At present, more than 3,000 square meters of workshops have been put into use, and the future workshops are under planning.

According to the product production process and process, reasonably plan the layout of the factory building, and carry out efficient management and production.

The clean production workshop is maintained by professional technicians, and standardized operating techniques and processes ensure that the operation of every link in the production process is accurate.

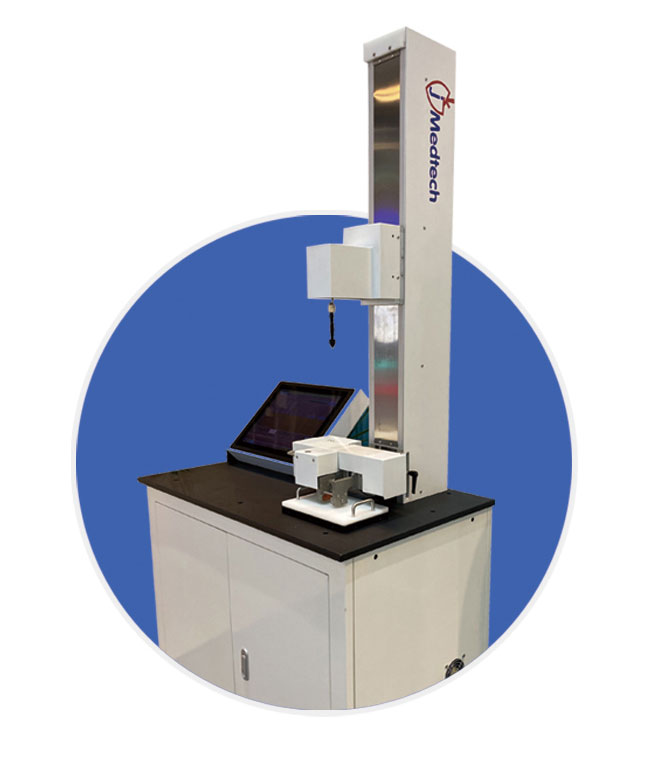

jMedtech provides customers with one-stop medical coating solutions from coating product development and production, coating equipment and testing equipment construction, product registration services, process technology training, coating OEM production services, and after-sales technical services.

jMedtech Coating provides one-stop service. From pre-sales to after-sales, there are dedicated personnel responsible for follow-up and providing services, paying attention to every detail in the production research of the customer's enterprise.

In 2015, jMedtech Coating completed the ISO13485:2003 certification. In many aspects of production and sales, the company strictly follows the requirements of the ISO system to ensure that high-quality products are provided for end customers.

The company holds a self-developed medical coating patent, and its patent scope covers China, the United States, Europe, Japan, etc., creating a complete and solid intellectual property shield.

jMedtech has a series of proprietary hydrophilic super-slip coating formulations and advanced UV curing technology.

In addition to common plastic pipes, such as polyurethane (TPU), polyetheramide (Pebax) and nylon (PA), it can also be widely used in a variety of difficult-to-coat materials, including: polypropylene (PP), polyethylene ( PE, HDPE, LDPE), polyimide (PI), silica gel, latex, fluoroethylene propylene (FEP), polytetrafluoroethylene (fluorine-containing materials such as PTFE, ETFE), metal, etc. Basically covers all polymeric organic compounds.

Cardiovascular catheters Cardiovascular catheters

Urology catheters Urology catheters

Vascular catheters Vascular catheters

Neurovascular catheters

Balloon catheters Balloon catheters

Stent delivery system Stent delivery system

Loach guide wire PU jacket guidewires

Metal guidewires Metal guidewires

Disposable Endoscopic Catheters